Profile Racing’s Legacy: Week 43, 2011.

After a year of planning and prototyping, a completely fresh crank design came from the mind of Jim Alley in 2011.

Taking the basic concepts from the classic, 19mm Profile Race Crank, and adding on several new dimensions, the Profile 22mm Elite Crank saw the light of day.

Original, aluminum crank arm press fixtures. The actual production press pieces would be made from steel.

“We wanted to make a very light weight, chromo crank that could compete with the 24mm, forged cranks that were becoming more popular on the market. With a triangular gusset, and both pedal and spindle welded caps, the Profile Elite Cranks substantially reduces flex and twisting, to make a much more rigid crank for the track.”

-Jim Alley

The original prototype Elite Crank was fabricated by Jim. He mentions that the most difficult part of getting the prototypes to work, was welding the tabs/caps on both ends of the crank arm due to the tubing being much thinner than the classic 19mm cranks. Next came the welding of the gusset.

Although this prototype was crude, it set the template for the 2nd and finally the 3rd version which became the final, production model.

Jim also mentions that thinner tubing was chosen due to the facial width of the crank arm. Wider = more rigid = allows for thinner tubing. When the tubing was swadged/pressed, the fixture also allowed for a slight bend mid crank arm which allows for clearance of the rider’s ankle (while pedaling) away from the spindle boss.

Left: Heat Treated Elite Arm. Right: Completely finished, Chrome Elite Arm. Notice the bend halfway down the arm which provides ankle clearance away from the spindle boss.

As opposed to our 19mm Race Cranks, the amount of welding time also doubles on the Elite Cranks. To offset the increase in production time in relation to cost, Profile decided that the finished product would include both a Spline Drive 4 -Bolt Spider and 22mm Outboard BB kit.

What other subsequent specs set the Profile Elite Cranks apart from forged equivalents?

- Made from 4340 heat-treated chromoly tubing as opposed to forged aluminum.

- Unlike other cranks on the market, the triangular gusset of the Elite arms eliminates any chance of the arm flexing from side to side or downward to deliver maximum pedal power.

- The Elite cranks come standard with a 22mm Ti axle, giving the Elite cranks the status of being one of the lightest cranks on the market.

- Bottom bracket uses 22mm cartridge bearings for less spinning resistance and increased durability.

- 3-piece crank construction: You can change arm sizes, replace damaged arms or spider/chainwheel without buying a new crankset (an advantage over 2-piece designs).

- Instead of using a spider, Profile offers the Sabre, one-piece sprocket as an alternative drive train in sizes 36 through 45t.

- Limited Lifetime warranty to the original purchaser on crank arms and spindle.

Besides the Pedal and Spindle bosses (not shown), here are the three, raw elements that make up the Elite Crank Arm.

Other aesthetic options on the Elite Cranks:

- Six crank arm lengths: 170mm – 172mm – 175mm – 177mm – 180mm and 182mm.

- Arms available in Black, White and Chrome, Spider and BB available in black, polished, red, blue, green and gold.

Image created by Adi Gilbert, based off an original photo of Jim Alley welding a batch of Elite Cranks.

The 22mm Profile Elite Cranks quickly became a staple in our inventory. 8 years later, it remains as one of the most Iconic pieces of fabrication that we’ve created in our machine shop.

In addition, 2011 saw the initiation of our Elite MTB line of product. Progressing from our “Classic” MTB designs begun in the late 90’s, Corey Alley took the Elite BMX Driver mechanism and applied it to two hubs (which would remain our staple up until this day): An Elite MTB 1-Speed Rear Disk Hub and an Elite MTB 9/10/11 Speed Rear Disk, Shimano compatible Hub.

The 1-Speed hub came out of the gate with two driver options; One compatible with Profile Cogs (seen below), and one compatible with Shimano Cogs.

The Elite MTB Rear 1-Speed Hub.

Universalizing the Elite MTB front hubs, two shells were made; a Disk and a Non-Disk version.

Instead of having multiple front hub designs with multiple axles, the only option you had to choose for the initial build was having a disk or not. From there, the hub was designed (using different internal axles instead of completely different shells) to be compatible with 15mm, 20mm, 3/8 bolt on or 3/8 QR.

This universality made our massive inventory of options much more streamlined.

These hubs opened up a full line for Profile to compliment MTB rigs…we will get to that in subsequent years.

In 2011, Madera got cranking again with product. Like 2010, the following year (2012) would be pivotal for our sister brand.

Leading up to that, the Madera Helm Spline Drive Sprocket saw the light of day.

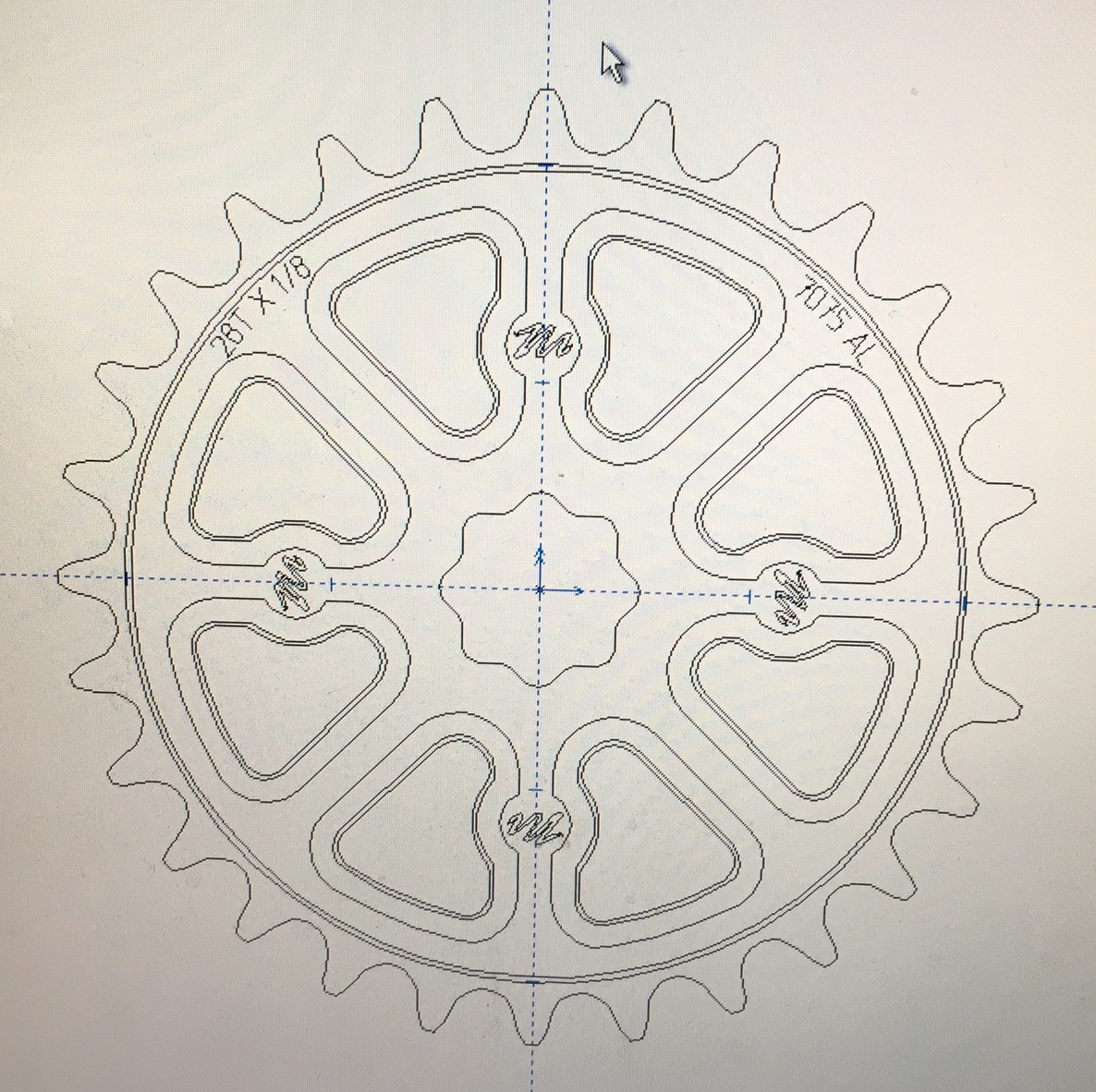

Here’s a CAD drawing of what we released at Interbike in 2011.

The Madera Helm would reveal itself in 19mm, in both 25t and 28t, in black ONLY at the time.

Soon after, Rust, Snow, Matte Red, Nickel and high Polished would follow.

The Original CAD drawing of the Madera Helm Spline Drive Sprocket.