Down to the Basics: Broaching.

Over the next couple weeks, we’re going to go over the seven, basic machine processes that go into making our parts; Turning, Hobbing, Milling, Tapping, Boring, Parting, and Broaching.

Although there are numerous post-production steps that go into finishing a Profile Racing part, this is where it starts.

Up seventh: Broaching.

There are two main types of broaching: Linear and rotary.

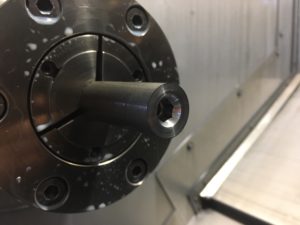

Rotary broaching is when the part turns, and the tool rotates when engaged, powered by the rotation of the part.

Every hex style bolt manufactured at Profile, is done with a rotary broach.

Finished Profile 17mm Hex Bolt.

Linear Broaching (Not shown here), is where the broach is either pushed or pulled through the part.

The spindle bosses on our cranks are an example; done twice, once to form the 48 splines, and twice to clean for final sizing.