Down to the basics: Hobbing

Over the next couple weeks, we’re going to go over the six, basic machine processes that go into making our parts; Turning, Hobbing, Milling, Tapping, Boring and Broaching.

Although there are numerous post-production steps that go into finishing a Profile Racing part, this is where it starts.

Up Second: Hobbing

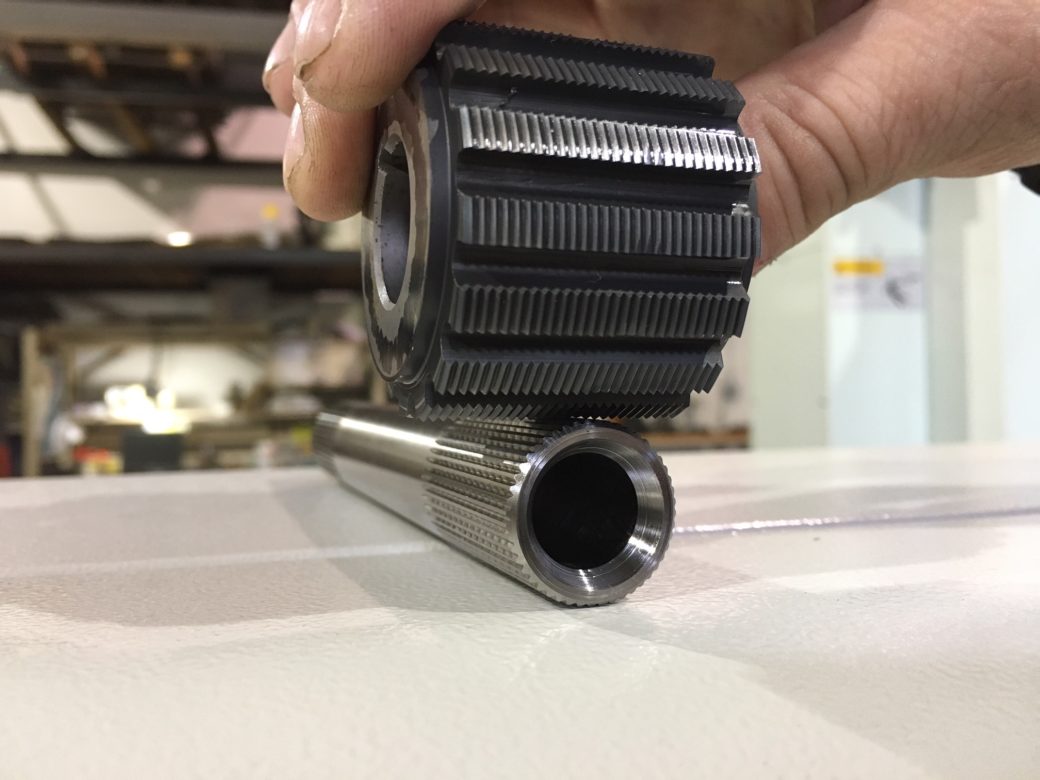

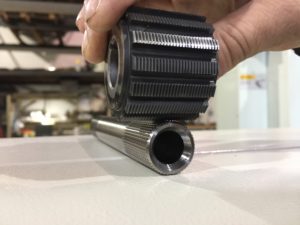

Profile’s current Hobbing tool that cuts splines into our 48 spline spindles: two sizes, 19mm and 22mm.

Hobbing is the action of gear cutting; both the Hobbing tool and part move in synch, if not, the splines can become twisted like a barber pole.

A Profile Racing, 19mm, 48 splined spindle after both end have been hobbed.

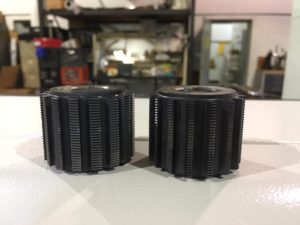

The Hob Tool goes through 1200 Chromo Spindles and or 720 Titanium spindles before needing to be re-sharpened. In this photo, a sharpened tool is on the left, and a dull tool is on the right.

Next week, Milling.

Thanks for the continued support.