Down to the Basics: Boring.

Over the next couple weeks, we’re going to go over the six, basic machine processes that go into making our parts; Turning, Hobbing, Milling, Tapping, Boring and Broaching.

Although there are numerous post-production steps that go into finishing a Profile Racing part, this is where it starts.

Up Third: Boring.

Boring needs an existing hole whether it’s pre-drilled or tubing. Boring can enlarge a hole, improve finish, and do some internal shaping.

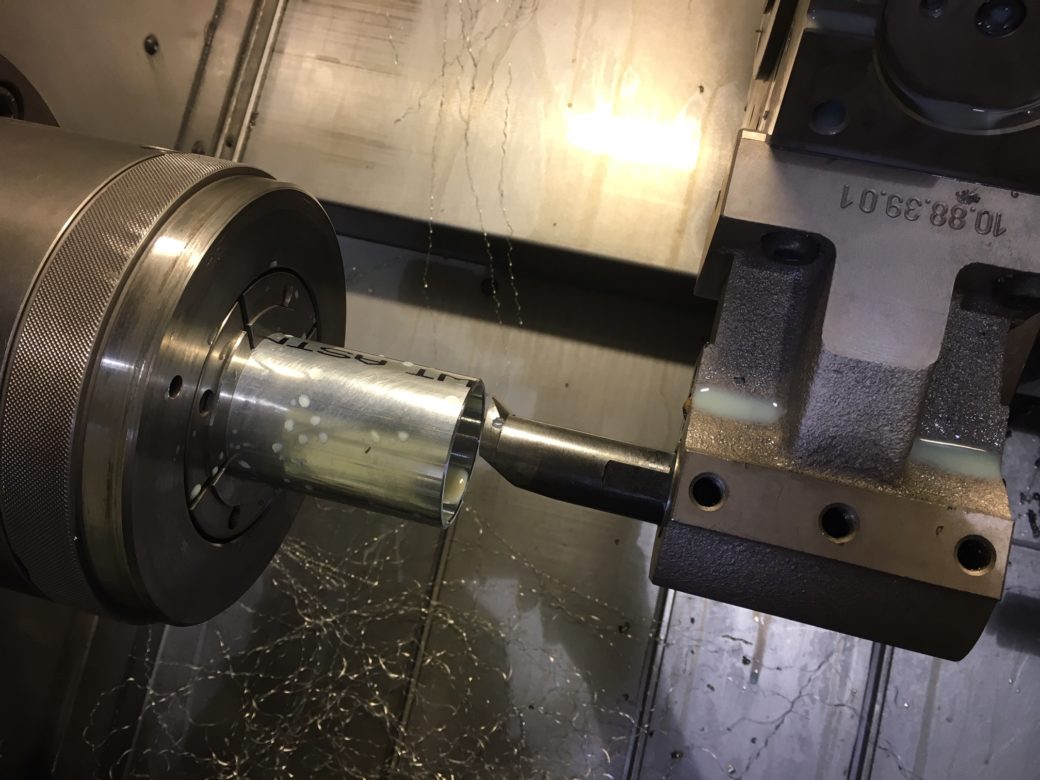

All of our Bottom Brackets cups have bore work; Inboard Euro, Outboard Euro, and pictured here, the American Press-in Cup. On the American cup, the boring bar bores the bearing pocket and the internal chamfer.

On our hubs shells, the drive side of the shell gets both a bearing bore and a driver bore which is much more work.

Thanks for the continued support, we’ll see you next week.