Profile Racing’s Legacy: Week 41, 2009.

Although we’ve mentioned in a previous post, that some of our most productive and innovative years were between 2007 and 2010, we can’t fully grasp at what level, comparatively, until we actually dive into the archives.

2009, in sheer numbers, might have been our MOST productive year in the machine shop for new product.

Our 2009, new product catalogue was just a sample of what was to come.

Laid out by Adi Gilbert in mid 2009, our catalogue features these fresh, either revised, or brand spanking new products:

- On Mulville’s request, we brought back the Ripsaw II sprocket but in smaller sizes. The original run in the 90’s only went as low as 39t, so in 2009, we made them in all stock colors in 25t, 28t, and 30t.

- After a year of prep work (considering the fabrication of the vintage cranks is incredibly in depth), Re-pop Vintage Cranks were released initially in low numbers in black. This was a period in time where chrome finish in the US was incredibly difficult to get done properly. By 2010, we had sourced a new Chromer in the South. And after dialing in some samples, moving forward, we only offered them in chrome.

- For a very short period of time, we offered 8t Drivers for our mini hubs to be paired up with 23t Imperial and Wake Sprockets. The 8t featured a new, bushing design and served well for those looking to lighten up their rigs, but also to keep your chain closer to the chain stays when riding street (in case of peg slippage).

- With the help of Chad Degroot and Mark Mulville, Profile released its first Pivotal Seats. Degroot’s on the left, Mulville’s on the right.

The three components on the list that either became iconic or set the standard for future products were:

- First and foremost, the 19mm Chromo GDH Spindle which became our standard. “GDH” stands for “Gun Drilled Hollow” : That machining process maintained the durability of the spindle (which transcended into later 22mm cranks by both Profile and Madera) but reduced the weight by 28%. These spindles also come with hollow chromo bolts.

- 2009 was the initiation of the “No Boss” crank. Considering the No Boss version of our standard 19mm cranks was something as simple as NOT welding in a spider boss (For a sprocket bolt), we produced these first to gain attention for what was to come at Interbike 2009 (See below).

- The return of the Gas Pedal in a slimmed down version. The new Gas Pedal took the original version from 1997/1998 and basically squashed them into half the pedal height. Due to the incredibly difficult machining, and the precision needed to match the bushing to the spindle to the pedal body, the grand total for production laid around 200 sets. The pedal was so sought after, that even our Freestyle TM, Matt Coplon, ended up buying back 4 pairs from other riders for his personal rigs.

Now, what was to come…

By Interbike, in September of 2009, we revealed two components that were fresh out of the machines:

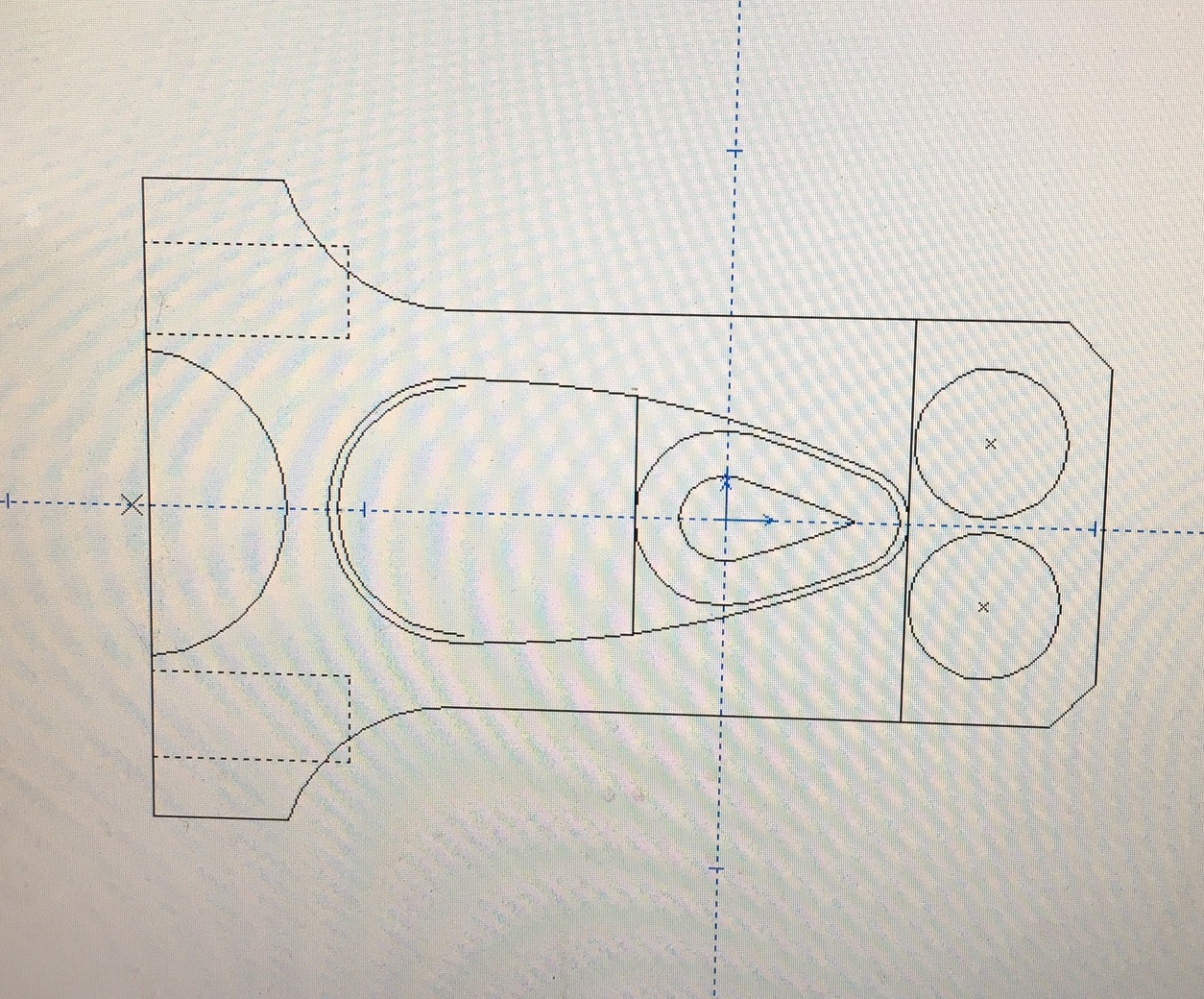

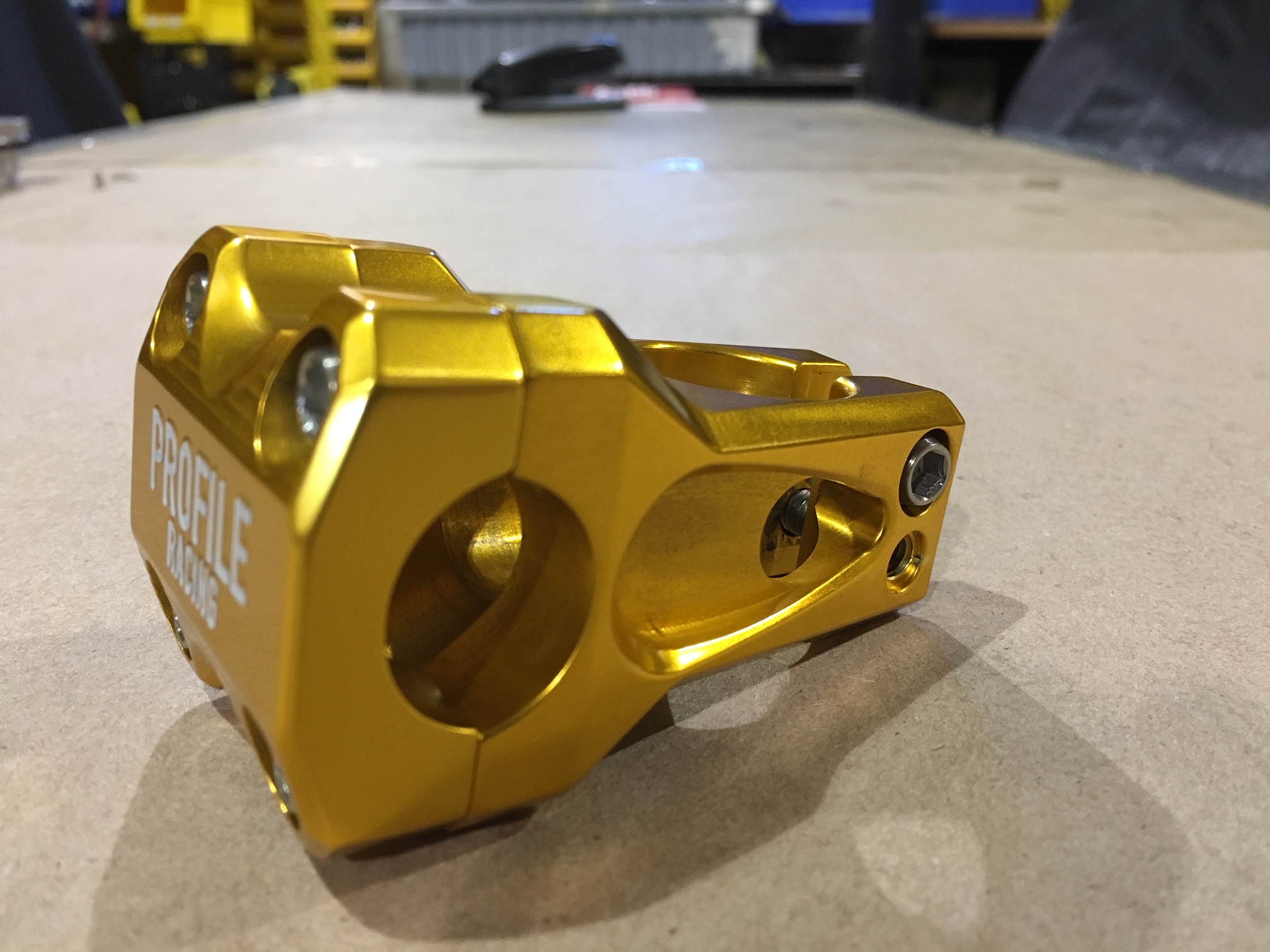

- The Micro Mini Acoustic Stem. For the junior riders, modeled directly off the Acoustic stem, this stem came (and is still available) in 35 and 42mm and in all of our staple colors. This is the only stem Profile has manufactured that has a full drilled-through body.

CAD drawing of the Micro Mini Acoustic Stem.

42mm in gold. Still a staple size and color.

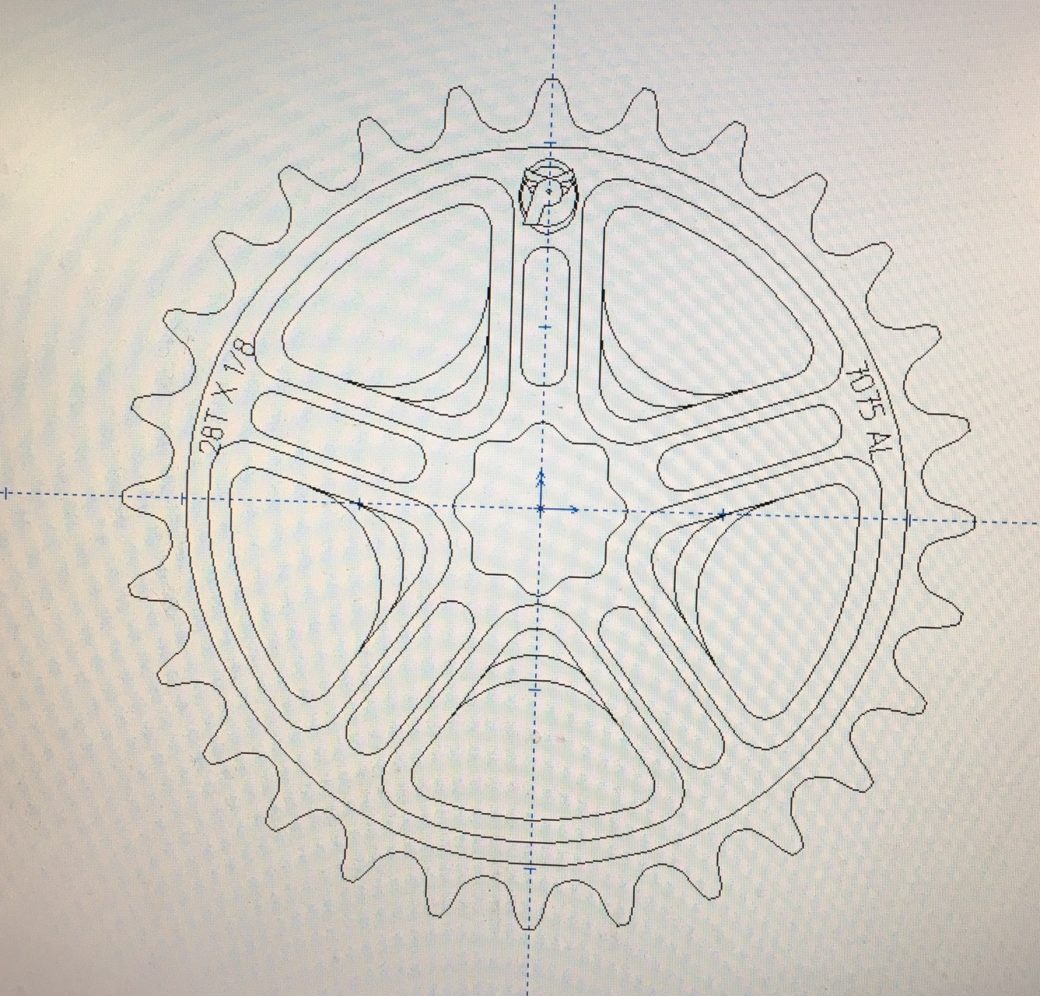

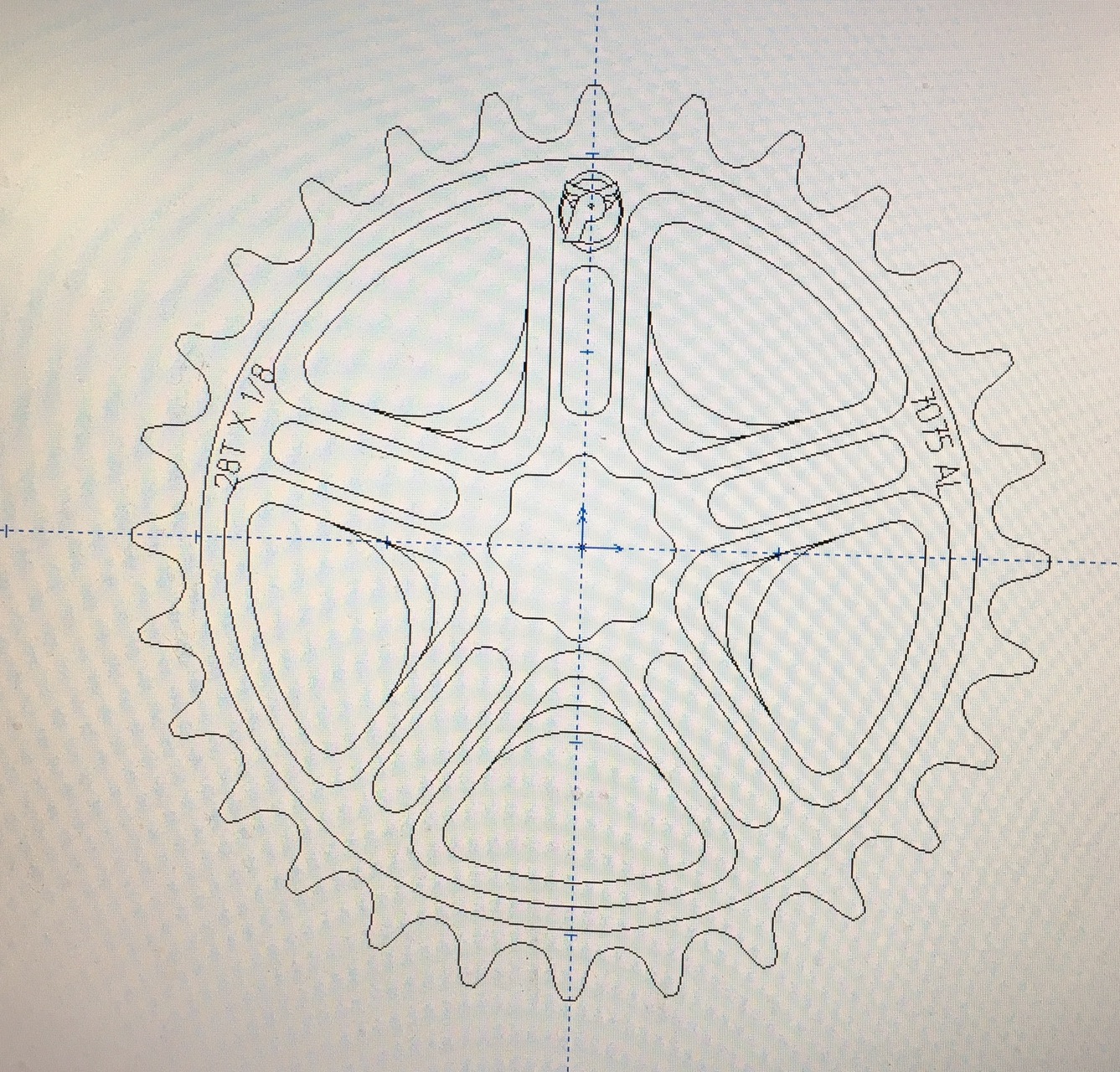

2. The initiation of our first production run of 19mm Spline Drive Sprockets. Going back into Profile’s history, round about 1982/1983, we tested the spline drive system on an early version of our spiders. Considering the spindle’s splines met directly with an aluminum counter part, we learned that the aluminum was too soft and too thin. Unfortunately, the project was abandoned pretty quickly.

With this newer version, Corey Alley designed an 8 sided, flower shaped, chromo/heat treated insert that was 6mm thick. This insert pressed into a 1/4″, 7075 aluminum sprocket. When wedded together, the system worked perfectly with our No Boss Cranks (No spider bolt needed, listed above), and quickly became our new, staple drive-train system that extends into today.

CAD drawing of our initial, 19mm spline drive sprocket in 28t.